Abrasablast vapourblasting Service

Abrasablast Australia

Precision wet graded glass-bead blasting process

|

|

| Alloy crankcase as received | Alloy crankcase AFTER Abrasablast vapourblast treatment |

Abrasablast:

Component surface restoration using our specialised Vaqua process

Collector car, veteran, vintage & classic car, motorcycle & commercial vehicle restoration projects.

Abrasablast vapourblasting process provides the ultimate in cleaning and surface preparation for your automotive parts.

With our precision Vaqua process there is NO IMPREGNATION or component erosion, no damage to sharp edges and precision surfaces, no loss of definition to engraved or stamped detail

The vapourblasting process is not only one of the world's fastest, most efficient and most economical metal cleaning and finishing systems, it totally eliminates the health and environmental hazards associated with strong chemicals and dust associated with other conventional methods.

What this means for you, our customer, is a better job, produced more rapidly and with greatly reduced cost and environmental impact

Abrasablast is the answer for all your component cleaning and surface preparation prior to polishing, painting, coating, plating or bonding

Unique Vaqua process uses graded, wet spherical glass beads to remove all surface contaminants, totally replacing solvent brushing, grinding and chemical immersion

Critical tolerances, threads, bearing surfaces & delicate engraved or stamped details are all fully maintained.

Our vapourblasting provides the ultimate in cleaning and surface preparation for your parts.

|

|

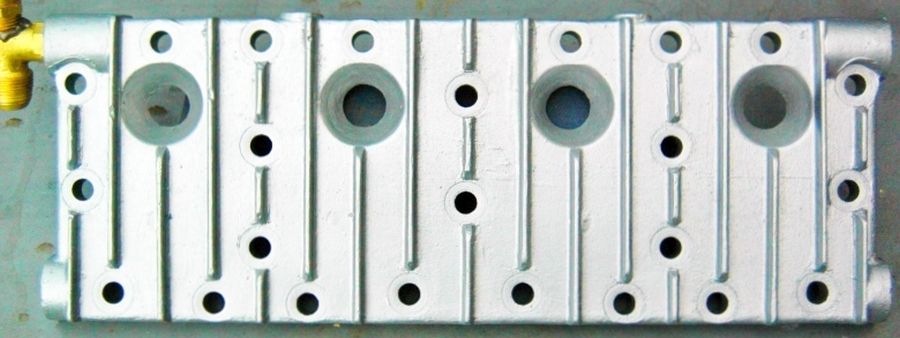

| Badly corroded alloy housing | After Abrasablast vapourblasting process; 100% clean, all corrosion removed, seals & rubber parts unaffected |

|

|

| Alloy Ford cylinder head as removed from engine | Alloy Ford cylinder head after our vapourblast process |

Advantages of having your job Vapourblast processed by the specialists: Abrasablast

· Precision Vaqua-process cleans with graded wet glass-beads and provides simultaneous removal of oil,

grease, burnt on carbon, paint, scale, oxides & other soil material.

· Environmentally reduced hazard - no toxic or harmful chemicals are used and no atmospheric pollution is

generated.

· No component erosion or impregnation - critical tolerances including bearing sizes, threads, sharp edges,

delicate etchings & precision surfaces are maintained.

· Flash rusting inhibition for ferrous metal surfaces can be applied if requested.

· Superb, superior finishes are obtained to prepare surfaces for either further polishing, paint application,

anodising or plating.

· Abrasablast can process items up to 700mm square and 200Kg mass in our enclosed cabinet Vaqua system

· Rapid turnaround guaranteed; our trade customers rely on our speed and precision, you can trust

Abrasablast with components from your special project too

Call or email for all your blasting requirements today

Ph: 0417 765 654

Email: Please use contact form on front page

Categories

Categories Shopping Cart

Shopping Cart